Features & Benefits

Fully configurable fail-safe

Setting of position (extended, retracted) or intermediate position, flow or power. Possibility to set delay for entering/leaving failsafe mode for a reliable and optimal fail-safe function. Ability to perform quick health check of fail-safe function.

Best-in-class control

Accurate and fast control response even at very low flows in common part load conditions. Ensures full modulating control for the complete operating stroke leading to world class control and efficiencies.

Optional cloud connection

Easy remote access to data and configuration parameters allows to verify and adjust system performance.

Optional ΔT and temperature return limitation

Optimize the efficiency of your production units by ensuring optimal temperature regimes.

Change-over functionality

Possibility to switch between two operating conditions to manage seasonality or heating and cooling with the same valve in change-over applications.

High measurement accuracy

High flow and temperature measurement accuracies in all configurations (medium type, and temperature) for all flow regimes.

Compactness and limited number of components

Reduces installation time and space requirements facilitating retrofit installation.

Convenient, reliable setup

Fully customizable and commissionable using Bluetooth enabled smart device reducing commissioning and diagnostic time.

Versatility in communication

Digital (key Bus protocols and MQTT) and Analog (0(2)-10 VDC or 0(4)-20 mA).

Technical Information

Application:

Heating (not steam) and cooling systems.

Functions:

Electronic fail-safe function

Control (flow, power, position)

Pre-setting (max./min. flow, max. power, max./min. position)

ΔT and temperature return limitation

Reading (flow, power, energy, supply/return temperature, ΔT, position)

Change-over function

Manual override (via HyTune app)

Mode, status and position indication

Valve blockage protection

Valve clogging detection

Error safe position

Diagnostic

Logging

Delayed start-up

Fail-safe function:

Programmable actuator’s stem extended, retracted or intermediate position, flow or thermal power on power supply failure.

Dimensions:

1/2" – 5"

Pressure class:

1/2" - 2": PN 25 (362 psi)

2 1/2" - 5": Class 150

Differential pressure (ΔpV):

Max. differential pressure (ΔpVmax): 58 psi

Closing pressure: 87 psi

ΔpVmax = The maximum allowed pressure drop over the valve to fulfill all stated performances.

Flow range:

The flow ranges (qsetmin - qnom) for different dimensions:

1/2": 0.70 - 5.28 gpm

3/4": 1.67 - 8.37 gpm

1": 2.38 - 11.89 gpm

1 1/4": 4.05 - 20.2 gpm

1 1/2": 6.86 - 34.3 gpm

2": 11.8 - 59.0 gpm

2 1/2": 25.5 - 128 gpm

3": 38.0 - 190 gpm

4": 62.5 - 312 gpm

5": 98.6 - 493 gpm

Minimum controllable flows (qcontr.min) size 1/2" 0.33% of qnom, sizes 3/4" - 5" 0.5% of qnom.

qsetmin = Minimum settable flow.

qnom = Maximum settable flow.

Measurement accuracy:

Flow:

Water: From 2% accuracy at 100% of qnom to 2.4% accuracy at 5% of qnom (according MID-Class 2 EN1434).

Water+glycol: From 3% accuracy at 100% of qnom to 4% accuracy at 5% of qnom (according to MID-Class 3 EN1434).

(see “Flow accuracy”)

Temperature difference:

±0.1 K @ ΔT = 6 K (for cooling)

±0.15 K @ ΔT = 10 K (for heating)

±0.2 K @ ΔT = 20 K (for heating)

Flow control accuracy:

±5% from 4% to 100% of qnom

±10% from 0.5% to 4% of qnom

Temperature:

Max. working temperature: 230°F

Min. working temperature: 14°F

Operating environment: 32°F to 122°F (5-95%RH, non-condensing)

Storage environment: -4°F to 158°F (5-95%RH, non-condensing)

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Leakage rate:

1/2" - 2": Leakage rate <0.01% of qnom with correct flow direction (Class IV according to EN 60534-4)

2 1/2" - 5": Tight sealing with correct flow direction (Class V according to EN 60534-4)

Characteristics:

Settable: Stepless between EQM 0.25 and inverted EQM 0.25.

Supply voltage:

24 VAC/VDC ±15%.

Frequency 50/60 Hz ±3 Hz.

NOTE: 24 VAC/VDC power supply must be provided only with safety isolating transformer according to EN 61558-2-6.

Power consumption:

1/2" - 2":

Peak: < 4.5 W (24 VDC); < 6.6 VA (24 VAC)

Operation: < 4.2 W (24 VDC); < 6 VA (24 VAC)

Standby: < 2.0 W (24 VDC); < 3.6 VA (24 VAC)

2 1/2" - 3":

Peak: < 10.5 W (24 VDC); < 18.4 VA (24 VAC)

Operation: < 6.1 W (24 VDC); < 11 VA (24 VAC)

Standby: < 2.1 W (24 VDC); < 4.1 VA (24 VAC)

4" - 5":

Peak: < 10.5 W (24 VDC); < 18.4 VA (24 VAC)

Operation: < 8 W (24 VDC); < 11.3 VA (24 VAC)

Standby: < 2.1 W (24 VDC); < 3.8 VA (24 VAC)

Peak consumption occurs for a short period after a power cut for recharging capacitors.

Input signal:

By BACnet/Modbus or Analog signal. Analog in VDC or mA, selectable by jumper in the SmartBox;

0(2)-10 VDC, Ri 47 kΩ.

Adjustable sensitivity 0.1-0.5 VDC.

0.33 Hz low pass filter.

0(4)-20 mA Ri 500 Ω.

Proportional:

0-10, 10-0, 2-10 or 10-2 VDC.

0-20, 20-0, 4-20 or 20-4 mA.

Proportional split-range:

0-5, 5-0, 5-10 or 10-5 VDC.

0-4.5, 4.5-0, 5.5-10 or 10-5.5 VDC.

2-6, 6-2, 6-10 or 10-6 VDC.

0-10, 10-0, 10-20 or 20-10 mA.

4-12, 12-4, 12-20 or 20-12 mA.

Proportional dual-range (for change-over):

0-4.5 / 5.5-10 VDC.

2-5.5 / 6.5-10 VDC.

0-3.3 / 6.7-10 VDC.

2-4.7 / 7.3-10 VDC.

0-9 / 11-20 mA.

4-11 / 13-20 mA.

Default setting: Proportional 0-10 VDC.

Output signal:

BACnet/Modbus

0(2)-10 VDC, max. 8 mA, min. 1.25 kΩ.

Fail-safe delay:

Adjustable between 0 and 10 seconds.

Default setting: 2 s

Pre-charging time:

1/2" - 2": < 40 s

2 1/2 - 3" < 60 s

4" - 5" < 125 s

Wireless:

Bluetooth Low Energy (BLE)

Thread

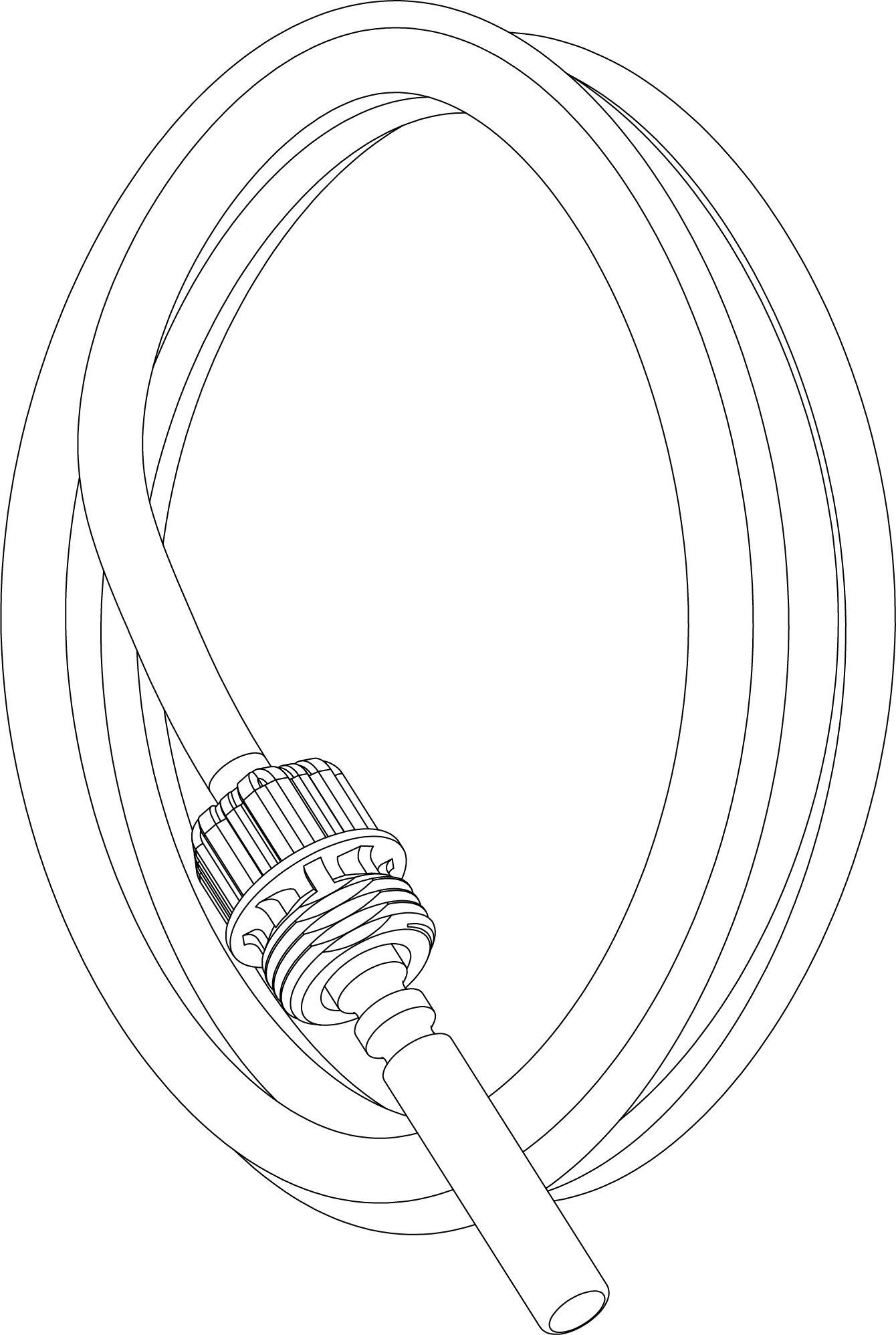

Temperature sensor cable:

1/2" - 2": 9.8 ft halogen free

2 1/2" - 5": 16.4 ft halogen free

32.8 ft. halogen free cable on request.

Ingress protection:

IP54

(according to EN 60529)

Protection class:

(according to EN 61140)

III (SELV)

Material:

Sizes 1/2" - 2":

Valve body: AMETAL®

Valve insert: AMETAL®

Valve plug: AMETAL® and PTFE

Spindle: Stainless steel

Spindle seal: EPDM O-ring

Internal plastic parts: PPS

Springs: Stainless steel

O-rings: EPDM

Temperature housing: AMETAL®.

Sizes 2 1/2" - 5":

Valve body: Ductile iron EN-GJS-400-15

Valve insert: Ductile iron EN-GJS-400-15 and brass

Valve plug: Stainless steel and EPDM O-ring

Valve seat: Stainless steel

Spindle: Stainless steel

Spindle seal: EPDM

Springs: Stainless steel

O-rings: EPDM

SmartBox (1/2" - 5"):

Cover: PC/ABS, red.

Housing: PC/ABS, TPE.

Actuators:

Sizes 1/2" - 2":

Cover: PC/ABS GF8, white RAL 9016, grey RAL 7047.

Housing: PA GF40.

Swivelling nut: Nickel-plated brass.

Sizes 2 1/2" - 5":

Cover: PBT, orange RAL 2011, grey RAL 7043.

Bracket: Alu EN44200

Wires: Halogen free

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Surface treatment:

1/2" - 2": Non treated

2 1/2" - 5": Electrophoretic painting

Pipe connection:

1/2" - 2": External thread according to ISO 228. Connections (accessories) with internal NPT according to ANSI/ASME B1.20.1-1983, or for soldering according to ASME/ANSI B16.18.

2 1/2" - 5": Flanges according to ASME 7 ANSI B16.42 Class 150.

Certifications and directives:

EMC-D. 2014/30/EU: EN 60730-1, -2-14.

Product standards EN 60730-x.

PED: 2014/68/EU

Articles

Including temperature sensor pocket and 16.4 ft. temperature sensor cable. (32.8 ft. cable on request, please contact IMI Hydronic Engineering)Free space >2.76 in. is required above the temperature pocket.

TA-Smart sizes 2 1/2" - 5"

Including temperature sensor pocket and 16.4 ft. temperature sensor cable.

(32.8 ft. cable on request, please contact IMI Hydronic Engineering)

Free space >2.76 in. is required above the temperature pocket.

Flanges according to ASME 7 ANSI B16.42 Class 150.

Size | Number of bolt holes | D [in] | L [in] | H [in] | Cvs | lb. | Article No |

Class 150 | |||||||

2 1/2" | 4 | 7.09 | 11.42 | 14.84 | 56.6 | 36.4 | 322233-01465 |

3" | 4 | 7.48 | 12.20 | 14.96 | 84.4 | 41.0 | 322233-01480 |

4" | 8 | 9.06 | 13.78 | 17.24 | 139 | 63.9 | 322233-01490 |

5" | 8 | 10.04 | 15.75 | 17.48 | 220 | 77.2 | 322233-01491 |

→ = Flow direction

Cvs = gpm at a pressure drop of 1 psi and fully open valve.

Including temperature housing and 9.8 ft. temperature sensor cable.(32.8 ft. cable on request, please contact IMI Hydronic Engineering)

TA-Smart sizes 1/2" - 2"

Including temperature housing and 9.8 ft. temperature sensor cable.

(32.8 ft. cable on request, please contact IMI Hydronic Engineering)

External threads according to ISO 228.

NPT threads - see "Connections".

Size | D | L [in] | H [in] | W [in] | Cvs | lb. | Article No |

1/2" | G3/4 | 6.57 | 6.81 | 3.82 | 2.20 | 3.09 | 322233-00115 |

3/4" | G1 | 7.09 | 6.85 | 3.82 | 3.64 | 3.53 | 322233-00120 |

1" | G1 1/4 | 7.36 | 6.85 | 3.82 | 5.03 | 3.97 | 322233-00125 |

1 1/4" | G1 1/2 | 7.87 | 7.83 | 3.82 | 8.44 | 4.63 | 322233-00132 |

1 1/2" | G2 | 8.58 | 7.79 | 3.82 | 14.3 | 6.61 | 322233-00140 |

2" | G2 1/2 | 9.41 | 7.79 | 3.82 | 24.5 | 8.60 | 322233-00150 |

Temperature housing incl. temperature sensor pocket

Included in TA-Smart sizes 1/2" - 2".

Internal thread NPT according to ANSI/ASME B1.20.1-1983.

Size | D1 | L1 [in] | H1 [in] |

1/2" | 1/2 NPT | 2.05 | 2.17 |

3/4" | 3/4 NPT | 2.17 | 2.20 |

1" | 1 NPT | 2.52 | 2.40 |

1 1/4" | 1 1/4 NPT | 2.60 | 2.79 |

1 1/2" | 1 1/2 NPT | 2.64 | 3.03 |

2" | 2 NPT | 2.68 | 3.50 |

For heating and non-condensing cooling applications.Material: EPP.Fire class: E (EN 13501-1), B2 (DIN 4102).

Insulation

For heating and non-condensing cooling applications.

Material: EPP.

Fire class: E (EN 13501-1), B2 (DIN 4102).

For size | L [in] | H [in] | W [in] | Ø [in] | EAN | Article No |

1/2" | - | - | - | - | - | - |

3/4" | 8.46 | 4.41 | 2.99 | 2.72 | 5902276819681 | 322230-00620 |

1" | 8.86 | 4.68 | 3.39 | 3.23 | 5902276819698 | 322230-00625 |

1 1/4" | 9.37 | 6.02 | 3.62 | 3.78 | 5902276819438 | 322230-00632 |

1 1/2" | 10.1 | 6.61 | 4.33 | 4.49 | 5902276819360 | 322230-00640 |

2" | 11.2 | 7.20 | 5.28 | 5.63 | 5902276819377 | 322230-00650 |

Included in TA-Smart.

Temperature sensor

Included in TA-Smart.

(32.8 ft. cable on request, please contact IMI Hydronic Engineering)

Tool for exchanging temperature sensor is included.

For size | Length [ft] | EAN | Article No |

1/2" - 1" | 9.8 | 7318794178229 | 322230-01106 |

1 1/4" - 2" | 9.8 | 7318794173705 | 322230-01100 |

2 1/2" - 5" | 16.4 | 7318794173804 | 322230-01101 |

Service tool

EAN | Article No | |

For exchange of temperature sensor | 7318794178144 | 322033-00000 |

For exchange of TA-Slider cable | 7318794178151 | 322033-00001 |

Included in TA-Smart sizes 2 1/2" - 5".For mounting directly on pipe. Free space >2.76 in. is required above the temperature sensor pocket.

Temperature sensor pocket

Included in TA-Smart sizes 2 1/2" - 5".

For mounting directly on pipe. Free space >2.76 in. is required above the temperature sensor pocket.

For size | D | L [in] | EAN | Article No |

1/2" - 1" | 1/4 NPT | 0.55 | 7318794174702 | 322230-00501 |

1 1/4" - 3" | 1/4 NPT | 1.18 | 7318794174801 | 322230-00500 |

4" - 5" | 3/8 NPT | 2.28 | 7318794178182 | 322230-00502 |

Included in TA-Smart sizes 1/2" - 2".

Temperature housing incl. temperature sensor pocket

Included in TA-Smart sizes 1/2" - 2".

To be ordered separately if the pipe size does not match the valve size.

Internal thread NPT according to ANSI/ASME B1.20.1-1983.

Size | D1 | L1 [in] | H1 [in] | Article No |

1/2" | 1/2 NPT | 2.05 | 2.17 | 322230-00315 |

3/4" | 3/4 NPT | 2.17 | 2.20 | 322230-00320 |

1" | 1 NPT | 2.52 | 2.40 | 322230-00325 |

1 1/4" | 1 1/4 NPT | 2.60 | 2.79 | 322230-00332 |

1 1/2" | 1 1/2 NPT | 2.64 | 3.03 | 322230-00340 |

2" | 2 NPT | 2.68 | 3.50 | 322230-00350 |

Threads according to ANSI/ASME B1.20.1-1983.Swivelling nut

With internal thread NPT

Threads according to ANSI/ASME B1.20.1-1983.

Swivelling nut

Brass/AMETAL®

For size | D | D1 | L [in] * | EAN | Article No |

1/2" | G3/4 | 1/2 NPT | 0.98 | 7318794017900 | 52 163-215 |

3/4" | G1 | 1/2 NPT | 0.71 | 7318794018303 | 52 163-320 |

3/4" | G1 | 3/4 NPT | 0.91 | 7318794018006 | 52 163-220 |

1" | G1 1/4 | 3/4 NPT | 1.06 | 7318794018402 | 52 163-325 |

1" | G1 1/4 | 1 NPT | 1.06 | 7318794018105 | 52 163-225 |

1 1/4" | G1 1/2 | 1 NPT | 1.06 | 7318794018501 | 52 163-332 |

1 1/4" | G1 1/2 | 1 1/4 NPT | 1.22 | 7318794018204 | 52 163-232 |

1 1/2" | G2 | 1 NPT | 1.18 | 7318794033108 | 52 163-340 |

1 1/2" | G2 | 1 1/2 NPT | 1.26 | 7318794032903 | 52 163-240 |

2" | G2 1/2 | 1 1/2 NPT | 1.26 | 7318794033207 | 52 163-350 |

2" | G2 1/2 | 2 NPT | 1.26 | 7318794033009 | 52 163-250 |

According to ASME/ANSI B16.18Swivelling nut

Soldering connection

According to ASME/ANSI B16.18

Swivelling nut

Brass/gunmetal CC491K (EN 1982)

For size | D | Pipe Ø [in] | L [in] * | EAN | Article No |

1/2" | G3/4 | 0.629 | 0.63 | 7318794022904 | 52 009-715 |

3/4" | G1 | 0.879 | 0.87 | 7318794023000 | 52 009-720 |

1" | G1 1/4 | 1.130 | 1.02 | 7318794023109 | 52 009-725 |

1 1/4" | G1 1/2 | 1.380 | 1.10 | 7318794023208 | 52 009-732 |

1 1/2" | G2 | 1.630 | 1.22 | 7318794033900 | 52 009-740 |

2" | G2 1/2 | 2.130 | 1.50 | 7318794034006 | 52 009-750 |

*) Fitting length (from the gasket surface to the end of the connection).

Other type of connections (ISO), see international version of TA-Smart.

Photos

TA-Smart_Fail-safe_external_front

Select a format Download

TA-Smart_Fail-safe_flanged_persp

Select a format Download

TA-Smart_Fail-safe_flanged_front

Select a format Download

TA-Smart_Fail-safe_group_vertical

Select a format Download

TA-Smart_Fail-safe_group

Select a format Download