Features & Benefits

High separation efficiency with Cyclonic technology

Cleans your system in fewer cycles, each time reducing dirt particles that would normally deposit in the system with each additional cycle. The dirt collected can be easily and quickly flushed out with the help of the drain valve.

High efficiency independent of dimension

Separation efficiency increases together with flow velocity. The pressure drop remains stable regardless of the amount of dirt collected. Even higher protection for higher flows, e.g. in cooling applications. Suitable for heating and cooling installations.

Cleans and protects the installation

Protects critical investments such as boilers, pumps, valves, chillers, and calorie meters, from dirt-related malfunction and failure. No risk of clogging - the dirt collected can be easily and quickly flushed out with the help of the drain valve. Reduces maintenance and associated costs over entire system lifetime.

Magnet Accessory

Optimizes separation efficiency even further for sludge and magnetite (black iron oxide) deposits that consist of finer magnetic particles. Easy handling and cleaning.

Air separation

Due to the cyclonic effect, pressure in the centre of the device is below system pressure, causing more air bubbles to be released than in standard separators. The air is concentrated in the centre forming larger bubbles, which can raise in the upper section of the G-Force where there is less flow. This function requires an additional ZUTX automatic air vent.

Technical Information

Application:

Heating and chilled water systems.

Media:

Non-aggressive and non-toxic system media.

Ethylene or propylene glycol-based antifreeze up to 50%.

Pressure:

Max. admissible pressure, PS: 232 psi and PN 25 (see each product)

Min. admissible pressure, PSmin: 0 psi

Temperature:

Max. admissible temperature, TS:

- PN16: 110 °C

- PN25: 180 °C

Min. admissible temperature, TSmin: -10 °C

Material:

Steel. Color beryllium.

Marking:

Body: flow direction arrow.

Label: DN, PN, tsmax and tsmin.

Connection:

Flanges according EN-1092-1.

Welding ends.

Grooved ends.

Transportation and storing:

In frostless, dry places.

Standard:

Constructed according to PED 2014/68/EU.

Articles

Flanged

Horizontal, vertical and lying installation.

PN16

Type | S [DN] | H | H1 | H2 | h1 | h2 | L | qnom [m3/h] | qmax [m3/h] | m [kg] | EAN | Article No |

ZG 65 | 65 | 815 | 420 | 395 | 685 | 645 | 350 | 10 | 40 | 23 | 7640161631489 | 303041-11000 |

ZG 80 | 80 | 900 | 445 | 455 | 710 | 705 | 470 | 18 | 56 | 37 | 7640161631496 | 303041-11100 |

ZG 100 | 100 | 960 | 445 | 515 | 710 | 765 | 475 | 37 | 95 | 40 | 7640161631502 | 303041-11200 |

ZG 125 | 125 | 1180 | 560 | 620 | 935 | 870 | 635 | 68 | 148 | 108 | 7640161631519 | 303041-11300 |

ZG 150 | 150 | 1250 | 560 | 690 | 935 | 940 | 635 | 100 | 216 | 118 | 7640161631526 | 303041-11400 |

ZG 200 | 200 | 1470 | 580 | 890 | 1065 | 1140 | 900 | 200 | 375 | 238 | 7640161631533 | 303041-11500 |

ZG 250 | 250 | 1705 | 630 | 1075 | 1115 | 1325 | 1100 | 345 | 575 | 443 | 7640161631540 | 303041-11600 |

ZG 300 | 300 | 1855 | 655 | 1200 | 1140 | 1450 | 1100 | 540 | 815 | 490 | 7640161631557 | 303041-11700 |

Flanged

Horizontal, vertical and lying installaton for high pressure/high temperature applications.

PN25

Type | S [DN] | H | H1 | H2 | h1 | h2 | L | qnom [m3/h] | qmax [m3/h] | m [kg] | EAN | Article No |

ZG 65 | 65 | 815 | 435 | 410 | 700 | 660 | 350 | 10 | 40 | 24,5 | 7640161632400 | 303041-31000 |

ZG 80 | 80 | 900 | 460 | 470 | 725 | 720 | 470 | 18 | 56 | 43 | 7640161632417 | 303041-31100 |

ZG 100 | 100 | 960 | 460 | 530 | 725 | 780 | 475 | 37 | 95 | 46 | 7640161632424 | 303041-31200 |

ZG 125 | 125 | 1180 | 575 | 635 | 950 | 885 | 635 | 68 | 148 | 130 | 7640161632431 | 303041-31300 |

ZG 150 | 150 | 1250 | 575 | 705 | 950 | 955 | 635 | 100 | 216 | 142 | 7640161632448 | 303041-31400 |

ZG 200 | 200 | 1470 | 595 | 905 | 1080 | 1155 | 900 | 200 | 375 | 355 | 7640161632455 | 303041-31500 |

ZG 250 | 250 | 1705 | 640 | 1065 | 1125 | 1315 | 1100 | 345 | 575 | 640 | 7640161632462 | 303041-31600 |

ZG 300 | 300 | 1855 | 665 | 1190 | 1150 | 1440 | 1100 | 540 | 815 | 715 | 7640161632479 | 303041-31700 |

Welded connection

Horizontal, vertical and lying installation.

PN 16

Type | S [DN] | H | H1 | H2 | h1 | h2 | L | qnom [m3/h] | qmax [m3/h] | m [kg] | EAN | Article No |

ZG 65 W | 65 | 815 | 420 | 395 | 685 | 645 | 340 | 10 | 40 | 19 | 7640161631564 | 303041-21000 |

ZG 80 W | 80 | 900 | 445 | 455 | 710 | 705 | 455 | 18 | 56 | 30 | 7640161631571 | 303041-21100 |

ZG 100 W | 100 | 960 | 445 | 515 | 710 | 765 | 460 | 37 | 95 | 31 | 7640161631588 | 303041-21200 |

ZG 125 W | 125 | 1180 | 560 | 620 | 935 | 870 | 615 | 68 | 148 | 97 | 7640161631595 | 303041-21300 |

ZG 150 W | 150 | 1250 | 560 | 690 | 935 | 940 | 615 | 100 | 216 | 102 | 7640161631601 | 303041-21400 |

ZG 200 W | 200 | 1470 | 580 | 890 | 1065 | 1140 | 880 | 200 | 375 | 220 | 7640161631618 | 303041-21500 |

ZG 250 W | 250 | 1705 | 630 | 1075 | 1115 | 1325 | 1080 | 345 | 575 | 408 | 7640161631625 | 303041-21600 |

ZG 300 W | 300 | 1855 | 655 | 1200 | 1140 | 1450 | 1080 | 540 | 815 | 446 | 7640161631632 | 303041-21700 |

Magnet Attachment. For retrofitting to mounting on site in the range Zeparo G-Force.T-branch with magnetic rod and pocket. To increase the magnetite capture.

Zeparo G-Force Magnet ZGM

Magnet Attachment. For retrofitting to mounting on site in the range Zeparo G-Force.

T-branch with magnetic rod and pocket. To increase the magnetite capture.

Heating, solar and cooling water systems.

Addition of antifreeze agent up to 50%.

ZGM for PS > 16 bar and/or TS > 110°C on request.

Type | PS [bar] | TS [°C] | m [kg] | L | EAN | Article No |

ZGM 65-100 | 16 | 110 | 3,1 | 261 | 7640161632301 | 303051-11000 |

ZGM 125-150 | 16 | 110 | 3,6 | 371 | 7640161632318 | 303051-11300 |

ZGM 200-300 | 16 | 110 | 4,0 | 481 | 7640161634794 | 303051-11500 |

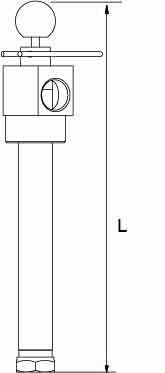

Male thread. Vertical installation.

Zeparo ZUTX eXtra-lockable

Male thread. Vertical installation.

Type | H | h1 | Weight [kg] | D | PS [bar] | EAN | Article No |

ZUTX 25 | 159 | 184 | 1,3 | R1 | 10 | 7640148632485 | 789 1325 |

dpu = Working pressure range

Pressure class reduced to PN 10 when ZUT is mounted

Thermal insulation for Zeparo G-Force.Heating water systems.

Zeparo ZGI

Thermal insulation for Zeparo G-Force.

Heating water systems.

Rockwool 2 part galvanized steel cladding, easy to fit with toggle clamps.

Insulation value approx. 0.0202 BTUH/ft.°F.

Fire rating A2 to DIN 4102.

Type | DN | SD* | H | D | m [kg] | EAN | Article No |

ZGI 65 | 65 | 40 | 520 | 305 | 2,8 | 7640161632325 | 303051-41000 |

ZGI 80 | 80 | 50 | 610 | 385 | 4,2 | 7640161632332 | 303051-41100 |

ZGI 100 | 100 | 50 | 670 | 385 | 4,6 | 7640161632349 | 303051-41200 |

ZGI 125 | 125 | 50 | 890 | 520 | 8,0 | 7640161632356 | 303051-41300 |

ZGI 150 | 150 | 50 | 960 | 520 | 8,7 | 7640161632363 | 303051-41400 |

ZGI 200 | 200 | 50 | 1130 | 720 | 22,0 | 7640161632370 | 303051-41500 |

ZGI 250 | 250 | 50 | 1350 | 930 | 38,0 | 7640161632387 | 303051-41600 |

ZGI 300 | 300 | 50 | 1470 | 930 | 41,5 | 7640161632394 | 303051-41700 |

*) Insulation thickness